Find ER4047 MIG, High Quality ER4047 MIG, ER4047 MIG Details on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

A. Description Tig Welding Wire ER4047 is a type of aluminum alloys wires containing 12% silicon, low melting point, good liquidity, good corrosion resistance, the color is ash black after anodic process. ER4047 aluminum & silicon is with high of crack resistance, but low plasticity, so for Plastic deformation joints after welding, we donor suggest it. You should strictly clean the oxide film on the edge of the workpiece and oil before welding. otherwise it will make bad weld produce and cause porosity, slag inclusion and other defects. Also you can use a plate to hold molten metal to ensure meld form. Usage: The argon arc Welding Wire of Al-Si, Al-Mg-Si, AI-Mg-Si-Cu Forging aluminum and aluminum(7%Si) is used as the filler material, And it has advantages of low melting point and good fluidity which avoids the distortion after welding .widely used in pure aluminum, Al-Mn, Al-Si-Mg alloys melding. B. Welding wire chemical composition (%)

A. Description Tig Welding Wire ER4047 is a type of aluminum alloys wires containing 12% silicon, low melting point, good liquidity, good corrosion resistance, the color is ash black after anodic process. ER4047 aluminum & silicon is with high of crack resistance, but low plasticity, so for Plastic deformation joints after welding, we donor suggest it. You should strictly clean the oxide film on the edge of the workpiece and oil before welding. otherwise it will make bad weld produce and cause porosity, slag inclusion and other defects. Also you can use a plate to hold molten metal to ensure meld form. Usage: The argon arc Welding Wire of Al-Si, Al-Mg-Si, AI-Mg-Si-Cu Forging aluminum and aluminum(7%Si) is used as the filler material, And it has advantages of low melting point and good fluidity which avoids the distortion after welding .widely used in pure aluminum, Al-Mn, Al-Si-Mg alloys melding. B. Welding wire chemical composition (%) hemical component(wt)/% |

Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Be |

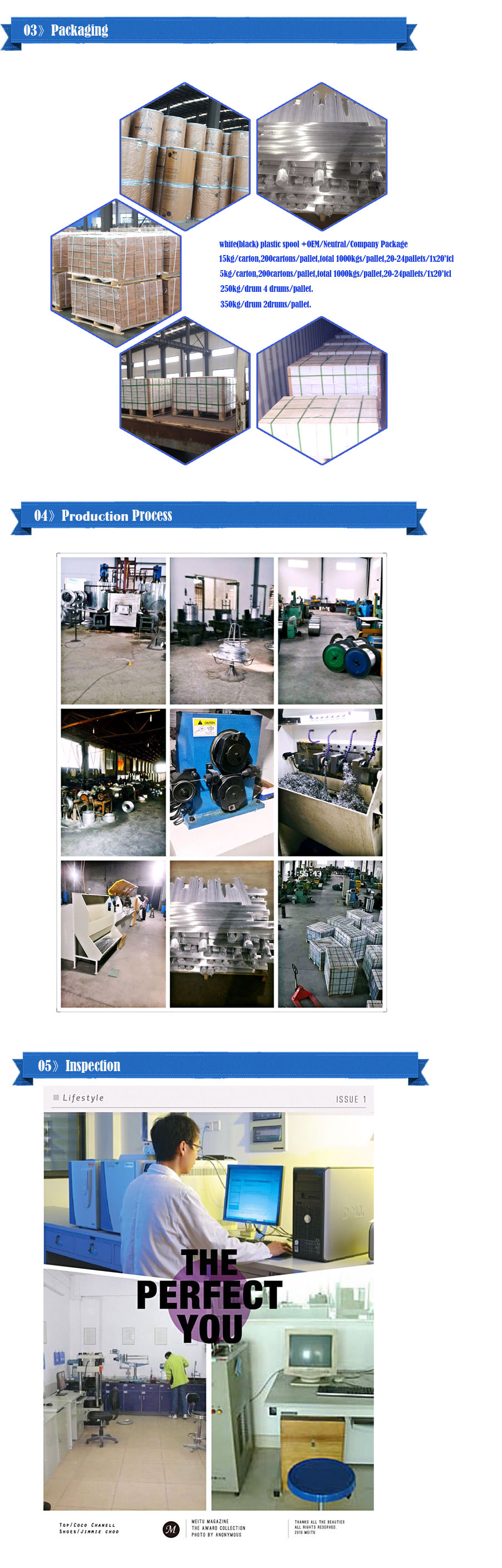

Lanxi Naihe Metalwork Co., Ltd., is one of leading manufacturing enterprises in China, specialized in making consumables like aluminum alloy wire and Aluminum welding Wire for 14 years. Professional production team, product line, experience technical experts who engaged in this industry for about 14 years, and all our PRODUCTS be exported to all of the world . Advantage of us: 1) We are manufacturer, fouce on the aluminum welding wire and rods 14 years, Following a variety of aluminum welding wire have excellent performance, stable arc, low spatter and small, good weld, high deposition efficiency. 2) Our products have these advantages, less smoke, less splash, plating finish, good fluidity . 3) We provide free technical training and solutions. If you have any question please feel free to contact us, we will be on hand to answer your questions. 4)Free Samples can be sent to check. 5)Accept the OEM. Lanxi Naihe Metalwork Co., Ltd., is one of leading manufacturing enterprises in China, specialized in making consumables like aluminum alloy wire and Aluminum welding Wire for 14 years. Professional production team, product line, experience technical experts who engaged in this industry for about 14 years, and all our PRODUCTS be exported to all of the world . Advantage of us: 1) We are manufacturer, fouce on the aluminum welding wire and rods 14 years, Following a variety of aluminum welding wire have excellent performance, stable arc, low spatter and small, good weld, high deposition efficiency. 2) Our products have these advantages, less smoke, less splash, plating finish, good fluidity . 3) We provide free technical training and solutions. If you have any question please feel free to contact us, we will be on hand to answer your questions. 4)Free Samples can be sent to check. 5)Accept the OEM.   Q1:Can I have a sample for testing? A: Yes, we can support free sample Q2:Can I add my logo on the boxes/cartons? A:Yes,OEM and ODM are available from us. Q 3: Waht are the benefits of being a distributor ? A: Special discount Marketing protection Q4:Do you have inspection procedures for welding wires? A:100% self-inspection before packing. We provide Quality Certification for every order . Q5:Can we mix itmes in one 20ft container? A: Yes Q6:Can I have a visit to your factory before the order? A: Sure,welcome your visit of factory. Here is our factory address:No.3 Huilan Road ,Lanxi city, China Dear, Why not sent me inqury now! Or call me at :0086--18606650086 Yours Jodie Sun Q1:Can I have a sample for testing? A: Yes, we can support free sample Q2:Can I add my logo on the boxes/cartons? A:Yes,OEM and ODM are available from us. Q 3: Waht are the benefits of being a distributor ? A: Special discount Marketing protection Q4:Do you have inspection procedures for welding wires? A:100% self-inspection before packing. We provide Quality Certification for every order . Q5:Can we mix itmes in one 20ft container? A: Yes Q6:Can I have a visit to your factory before the order? A: Sure,welcome your visit of factory. Here is our factory address:No.3 Huilan Road ,Lanxi city, China Dear, Why not sent me inqury now! Or call me at :0086--18606650086 Yours Jodie Sun  Contact us if you need more details on 4047 aluminum Welding Rod. We are ready to answer your questions on packaging, logistics, certification or any other aspects about ER 4047 aluminum welding rod、1.0mm ER 4047 aluminum welding rod. If these products fail to match your need, please contact us and we would like to provide relevant information. Contact us if you need more details on 4047 aluminum Welding Rod. We are ready to answer your questions on packaging, logistics, certification or any other aspects about ER 4047 aluminum welding rod、1.0mm ER 4047 aluminum welding rod. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Aluminum welding Wire > ER4047 MIG Other ProductsHot ProductsCarbon Steel ElectrodeTungsten Electrode WT20Resin Core Solder Wire 63/37Phosphorus Copper Brazing WireTin Brass Welding SolderSilver Brazing Alloy RodSilver Brazing AlloyPermanent Silver Brazing AlloyAWS E316L-16 Stainless Steel Welding RodWelding Electrode and Rod E7018Welding Electrode E6013A5.20 E71T-1 Flux Cored Welding WireSubmerged Arc Welding WireWelded Wire ER70S-6Stainless steel welding wire R316LAWS ER70S-6 Welding Wire |